- ・Hydraulic Component Tester

- ・Hydraulic Cylinder Service Stand

- ・Mobile Workshop, 4x4 Drive, Hydraulic & Mono_Rail Crane

- ・Mobile Workshop Truck 4x4 Rear Mounted Crane Type

- ・Lubrication Truck

Workshop Equipment and Tools

Hydraulic Component Reconditioning

Mobile Workshops

Off Road Tire / Wheel Equipment

- Max. Flow400 l/min

- Max. Pressure41.2 MPa (420 kgf/cm2)

- Max. Torque879 N·m (89.6kgf-m)

- Speed Range0 - 2650 rpm

- Max. Flow183 l/min

- Max. Pressure41.2 MPa (420 kgf/cm2)

- Max. Torque879 N·m (89.6kgf-m)

- Speed Range0 - 2650 rpm

- Max. Flow183 l/min

- Max. Pressure41.2 MPa (420 kgf/cm2)

- Max. Flow183 l/min

- Max. Pressure11.8 MPa (120 kgf/cm2)

- Max. Torque879 N·m (89.6kgf-m)

- Speed Range0 - 2650 rpm

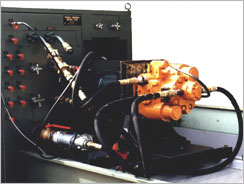

Control Panel (shown with analog gauges)

Control Panel (shown with analog gauges) Power Up Kit (Optional)

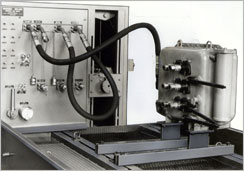

Power Up Kit (Optional) Single Pump

Single Pump Dual Pump

Dual Pump Plunger Motor

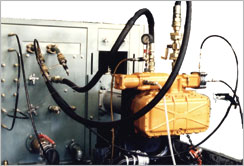

Plunger Motor Valve

Valve Cylinder

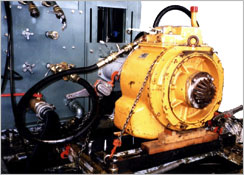

Cylinder Hydraulic Transmission

Hydraulic Transmission- DriveStarting TorqueApprox. 868 N·m (88.5 kgf·m)

- Speed0 - 2,700 min-1 (0 - 2,700 rpm)

- Charge Flow (H)Adjustable Flow0 - 183 L/min (50 Hz)

- Adjustable Pressure0.98 - 41.2 MPa (10 - 420 kgf/cm2)

- (rates are governed by the limitations of the electric motor)

- Charge Flow (L)Adjustable Flow0 - 183 L/min (50 Hz)

- Adjustable Pressure0.69 - 15.0 MPa (7 - 153 kgf/cm2)

- Lube Flow14 L/min, 0.34 MPa (3.5 kgf/cm2) (fixed)

- Sump Pump153 L/min (no load) (50 Hz)

- Load ValveAdjustable Pressure0.98 - 41.2 MPa (10 - 420 kgf/cm2)

- Filtration10 µm paper filter element

- Standard GaugesMain Control PanelPressure (analog)0.4 MPa (4 kgf/cm2)2 ea

- Pressure (analog)1.0 MPa (10 kgf/cm2)1 ea

- Pressure (analog)1.6 MPa (16 kgf/cm2)2 ea

- Pressure (analog)5.0 MPa (51 kgf/cm2)1 ea

- Pressure (digital)5.0 MPa (51 kgf/cm2)2 ea

- Pressure (digital)20 MPa (204 kgf/cm2)2 ea

- Pressure (digital)50 MPa (510 kgf/cm2)5 ea

- Tachometer (digital)0 - 9,999 min-11 ea

- Flow Meter (digital)30 L/min1 ea

- Flow Meter (digital)300 L/min2 ea

- Oil Temperature0 - 150℃1 ea

- Oil CoolerMain System134.4 MJ (32,000 kcal/h)

- Sub System218.4 MJ (52,000 kcal/h)

- Air Boost PressureAdjustable Pressure0.06 - 0.13 MPa (0.6 - 1.3 kgf/cm2)

- Safety Valve Set Pressure0.18 MPa (1.8 kgf/cm2)

- Electric MotorMain93 kW

- Sump3.7 kW

- Servo1.5 kW

- Hydraulic OilMain Tank400 L

- Sub Tank500 L (pressurized)

- Dimensions(L x W x H)Power Unit1780 x 1500 x 1750 mm

- Operation Unit1600 x 1950 x 1750 mm

- Sump Unit1830 x 1700 x 580 mm

- Shipping MassApprox. 4000 kg

HYDRAULIC COMPONENTS TESTER

93 kW OUTPUT MOTOR DELIVERS 125 HORSEPOWER FOR ACCURATE TESTING AND ADJUSTMENT FOR OPTIMUM PERFORMANCE OF HYDRAULIC COMPONENTS

DESIGNED FOR IN-SHOP TESTING OF HYDRAULIC

▶ PUMPS (Pump Efficiency, Cavitation, Temperature, Leakage, Pressure) ▶ MOTORS (Pump Efficiency, Cavitation, Temperature, Leakage, Pressure) ▶ CYLINDERS (Function, External & Internal Oil Leakage, Pressure) ▶ VALVES (Function, External & Internal Oil Leakage, Pressure, Pressure Drop) ▶ TRANSMISSIONS (Clutch Function, Oil Leakage, Setting Shift Points) ▶ TORQUE CONVERTERS (Oil Leakage)

Adjustment of the related control valves for pumps, motors and transmissions can also be performed.

DESIGNED FOR IN-SHOP TESTING OF HYDRAULIC

▶ PUMPS (Pump Efficiency, Cavitation, Temperature, Leakage, Pressure) ▶ MOTORS (Pump Efficiency, Cavitation, Temperature, Leakage, Pressure) ▶ CYLINDERS (Function, External & Internal Oil Leakage, Pressure) ▶ VALVES (Function, External & Internal Oil Leakage, Pressure, Pressure Drop) ▶ TRANSMISSIONS (Clutch Function, Oil Leakage, Setting Shift Points) ▶ TORQUE CONVERTERS (Oil Leakage)

Adjustment of the related control valves for pumps, motors and transmissions can also be performed.

FEATURES

-

Features of the MH-125D

1. The MH-125D is capable of testing a variety of hydraulic components of various machine manufacturers.

2. This tester can continuously supply a large volume of oil at a maximum pressure of 41.2 MPa (420 kgf/cm2)

3. The hydraulic line of the MH-125D is separated into 2 systems. One system consists of the main pump and motor, which drives the tester and the other system supplies the component to be tested. The systems have separate oil tanks, preventing the mixing of abrasive particles into the main tank from the test component. This improves the durability of the tester.

4. Safe operation is achieved with the operating position of the tester being square against the rotating plane of the test component shaft.

5. A hydraulic pressure servo controller for the test components is built in the tester. Two systems can be operated if the pressure is under 14.7 MPa (150 kgf/cm2).

6. Electric servo controllers can be built in, as an option, to easily test hydraulic components with electric type servo valves.

7. Accurately adjust the repaired or reconditioned hydraulic component for optimum performance.

Power Up Kit (Optional) To meet the demands of testing larger capacity hydraulic components, we developed the Power Up Kit. The Power Up Kit will increase the horsepower output of the hydraulic test bench, as well as increase the hydraulic flow pressure and drive torque.

An optional 1127 N·m (115 kgf·m) Drive Motor is also available when used in conjunction with the Power Up Kit.

Pump Test 1. Open type pumps (gear and vane pumps), closed type pumps and also plunger pumps with weak suction can easily be tested by the built in variable pressure booster.

2. Even a synchronous twin pump can easily be mounted on the test bench.

2. The rotatizonal direction of the motor is automatically changed according to the changing of the rotational direction of the work.

2. Test of function of direction control valve and also set pressure of the pressure-regulating valve can be fully conducted.

SPECIFICATIONS

* Please note that the indicated rates are theoretical values, and the actual rates obtained may vary according

to the existing conditions.

* Specifications and illustrations are subject to change without notice.

* Specifications and illustrations are subject to change without notice.

copylight (C) 2009 MARUMA ▶Terms of Use/Privacypolicy ▶SiteMap ▶Contact