- ▶Track Rebuilding

- ・Shoe Bolt Torque Controller

- ・Track Shoe Rebuilding Machine

- ・Track Link Welder

- ・Track Press 230 / 330

- ▶Roller and Idler Rebuilding

- ・Roller & Idler Press

- ・Roller And Idler Rebuilding Machine

- ・Mobile Workshop Truck 4x4 Rear Mounted Crane Type

- ・Mobile Workshop, 4x4 Drive, Hydraulic & Mono_Rail Crane

- ・Service Car

- ・Lubrication Truck

Workshop Equipment and Tools

Undercarriage Rebuilding

Hydraulic Component Reconditioning

Mobile Workshops

Off Road Tire / Wheel Equipment

- Optional jib crane and hoist.

- Roller work table can be moved into the press frame while front idler is being repaired.

- Press frameDimensions (W x D x H)2283 x 1000 x 1790 mm

- Net weight1000 kg

- Pressing force100 ton (metric)

- Cylinder bore diameter150 mm

- Stroke600 mm

- Ram speedApproach 2873 mm/min.

- Pressing 342 mm/min.

- Max. pressure58.8 Mpa (600 kgf/cm2)

- Press frameDimensions (W x D x H)590 x 450 x 980 mm

- Net weight308 kg

- Motor5.5 kW, 3 phase, 220 V

- 4 pole, 50/60 Hz.

- (Various voltages are available on request.)

Sizing discs

Sizing discs Bushing assembly tools

Bushing assembly tools

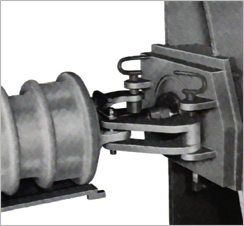

ROLLER & IDLER PRESS

FEATURES

SPECIFICATIONS

STANDARD ATTACHMENTS

-

Collar removing tools

After the snap ring has been removed, the track roller and collar can be disassembled from the shaft by using the collar removing tools as shown below.

OPTIONAL ATTACHMENTS FOR ROLLER & IDLER PRESS

-

Sizing discs

After welding the roller, it is often necessary to restore the bore to its original size. Now expensive boring equipment and labor is not needed. Sizing discs forced through the roller bores restore them to original dimensions in a few minutes.

Bushing assembly tools Precision bushing assembly tools allow rapid assembly with accurate bolt-hole alignment.

�E�Specifications and illustrations are subject to change without notice.

copylight (C) 2009 MARUMA ▶Terms of Use/Privacypolicy ▶SiteMap ▶Contact