- ▶Track Rebuilding

- ・Shoe Bolt Torque Controlle

- ・Track Shoe Rebuilding Machine

- ・Track Link Welder

- ・Track Press 230 / 330

- ▶Roller and Idler Rebuilding

- ・Roller & Idler Press

- ・Roller And Idler Rebuilding Machine

- ・Mobile Workshop Truck 4x4 Rear Mounted Crane Type

- ・Mobile Workshop, 4x4 Drive, Hydraulic & Mono_Rail Crane

- ・Service Car

- ・Lubrication Truck

Workshop Equipment and Tools

Undercarriage Rebuilding

Hydraulic Component Reconditioning

Mobile Workshops

Off Road Tire / Wheel Equipment

- The Model MTC-450 Hydraulic Shoe Bolt Wrench is specifically designed for assembling and disassembling for track shoe bolts on crawler type bulldozers and the like.

The Hydraulic Wrench has some big advantages over conventional impact wrenches.

1. Easy and accurate setting of the required torque.

2. Reduced noise level.

There is less chance of damage to shoe bolts and much more bolts are reusable when a hydraulic wrench is used instead of an impact wrench. It eventually helps to reduce the maintenance cost of a tractor.

- Output shafttorque 30 E450 kgf·m (294 ~ 4410 Nm)

- angle for additional turn 0 - 360°(subdivide 3.6°)

- number of rotations 16 E300 r.p.m.

- square drive 1-1/2 inch

- Electric Motor5.5 kW 3-phase 220/380V 50/60Hz (Various voltages are available upon request)

- Capacity of oil tank60 liter

- Dimensions (L x W x H)approx 2,200 x 1,200 x (1,400 ~ 1,670)

- weightapprox 750 kg

SHOE BOLT TORQUE CONTROLLER

FEATURES

・ Another device is contained which gives any additional turn after bolt is tightened at a given torque. Reduced noise level The noise level is lower than 75dB (A) at a point 1 meter away from the wrench. (In the case of conventional impact wrenches, the maximum level is over 120dB (A)) Hydraulic drive Hydraulic drive is preferable for accurate work and reduction of maintenance costs.

Having both a motor with low torque at high speed and a motor with high torque at low speed, work will be done

economically. That is, slowly at start of loosening stage or at the final stage of tightening where high torque is required, and quickly where low torque is required.

SPECIFICATIONS

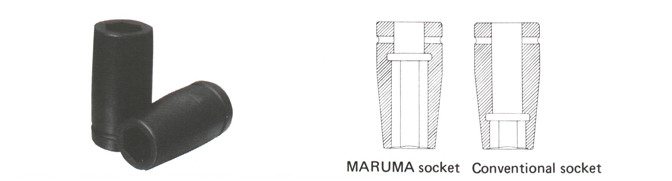

SPECIAL SOCKETS FOR SHOE BOLTS (PATENT PENDING)

Maruma sockets being of high alloy steel with deep hexagonal hole, can be used again and again by cutting and grinding the worn-out end of the socket. In such way it lasts more than ten times the life of conventional sockets on the market and it is very economical.

In addition to the standard size sockets for any machine model, the under-sized sockets for worn shoe bolts are also available. Contact Maruma for further details. �E�Specifications and illustrations are subject to change without notice.

copylight (C) 2009 MARUMA ▶Terms of Use/Privacypolicy ▶SiteMap ▶Contact